Do You Need Rock Breakers We Can Help With?

Products Range

Shawonga supplies a wide range of products covering materials handling equipment and tools, rockbreakers, underground loaders, white metal products, utility vehicles and back up spares.

We offer a wide range of rockbreaker systems suitable for raking and breaking in both stationary and portable crushing plants. The stationary rockbreaker system was developed to address production and safety concerns associated with the handling of oversize, material flow on grizzlies (ore passes), rockboxes and crushers. Often workers were exposed to dangerous situations such as having to dislodge jammed material from crusher jaws or slinging oversize material out of rockboxes.

Installing a stationary Rockbreaker system allows for economical, safe and efficient breaking of oversize material.

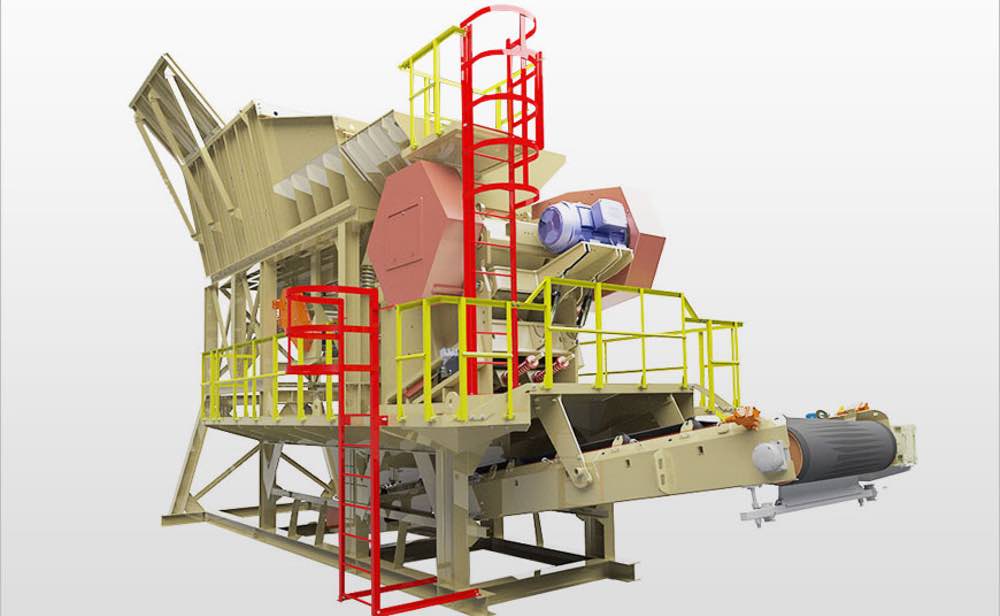

Breaker Technology now offers the world’s broadest selection of Stationary Rockbreaker Systems to effectively meet the needs of a variety of applications in the world’s crushing, mining and metallurgical industries.

The BTI hydraulic breakers mount on excavators, wheel loaders, skid steers and tractor backhoes, working across a wide range of applications including construction, quarry and mining.

BTI Rock Breakers

When it comes to reducing oversize rock in underground mining, BTI’s TM Series Mobile Rockbreaker quickly reduces oversize at girzzlies, stopes and draw points without explosives – improving safety, productivity and profitability. Its purpose-built heavy-duty, large cross-section boom provides excellent dexterity and strength when raking and breaking oversize material.

The Series offers four different models with a breaker class range between 2,000 and 8,500 ft-lb (BX20 to BXR85) hydraulic breaker attachment on a low-profile, side-mounted design for low tramming and operating heights. The four heavy-duty self-leveling stabilizers provide quick set-up time and stable operation while the 45-degree carrier articulation makes it easy to turn in tight spaces.

Visit BTI WebSite Here

Astec (Osborn)

Osborn Engineered Products is a leading name in global mining and quarry markets, providing a full range of engineering products, including crushers, feeders and screens and further specialises in crushing and screening plants. Osborn is a member of the Astec Industries Inc. group of companies – a leading American manufacturer of plant and equipment for aggregate processing and asphalt road building.

Osborn also deals with the full manufacturing process from concept and installation through to commissioning. Osborn has a solid reputation globally, with machines operating in the harshest of conditions. Osborn is devoted to meeting the needs and demands of its customers. These are our key company values for customer satisfaction.

Osborn has experienced impressive growth in the past five years and the company believes customer satisfaction is a primary driver of this growth. Engaging with Osborn is the start of a value driven partnership.

Osborn is a member of the United States based industrial group, Astec Industries. This valuable connection delivers exceptional benefits to Osborn customers as it augments our resources with the Astec Group’s extensive technologies, equipment, research and development, enabling international knowledge sharing and the transfer of skills.

• Crushers

• Feeders

• Screens

• Crushing Plants

• Screening Plants

PMSA

PAN MIXERS SOUTH AFRICA (PMSA) is Africa’s largest manufacturer of concrete brick, block and paving machinery, supplier of concrete pumps, planetary and twin-shaft mixers (Eurostar), turbine and counter-current rapid pan mixers (PMSA), moisture measuring systems (Franz Ludwig), oxide dosing systems (Finke Dosiertechnik), kerb stone machinery (Wil El Mil Engineering), concrete pipe machinery (BFS Casagrande), self-loading concrete mixers (Fiori), mixing and weigh batching plants (PMSA) and production pallets (MyWood).

Block Making Machines include the RE-1400, VB4X and the VB4 range of block making machines. Standard brick capacity is between 96,000 and 165,000 per 9-hour production shift, depending on machine option. The machines are supplied with the appropriate mixing plant and a choice of materials and pallet handling systems. The machines are fully automated and several options are available depending on products manufactured.

For more information, visit PMSA South Africa website

PMSA South Africa

Gray Tools

Since 1912, people who do extraordinary work have been using Gray tools. Whether you’re a miner working miles underground or a mechanic working on a jumbo jet, we understand there are times you need extraordinary sizes, styles, shapes, and lengths to get the job done.

It’s for this reason that we offer a large selection of unique tools, such as our 60″ pry bars, 4″sockets and combination wrenches, and strike-free wrenches.

To see all other ranges of Grey Tools equipment, visit our website here.

Bekalube

BEKALube South Africa offers a complete package of automatic lubrication solutions for the mining, construction and industrial industries.

BEKA is one of the world leaders in the development of lubrication technology. Standard products include dual line systems, injector systems and progressive technology. BEKA products are used worldwide in OEM applications and after sales installations.

Our Range of Industrial Lubrication Systems:

BEKA single line system

The single line system is suitable for small and medium-sized machines like e.g. machine tools, weaving machines and textile machines.

BEKA multi line system

The multi line system is used for machines with a low number of lube points, like e.g. compressors, chain lubrication and presses.

BEKA progressive system

The progressive system can be monitored easily and is suitable e.g. for presses, punches and cranes.

BEKA dual line system

The dual line system supplies large plants with wide spread lubrication points, like e.g. timber yards or rolling mills.

BEKA oil circulating system

BEKA oil circulating systems are designed and produced individually on customer’s demand.

BEKA gear pumps

BEKA produces a broad range of gear pumps and internal gear pumps.